How Temperature and Pressure Impact 6.7 Cummins Intercooler Boots Durability

The integrity and performance of the 6.7 Cummins engine rely heavily on the condition of its intercooler boots, which are subject to the rigorous demands of both temperature fluctuations and pressure variations. High temperatures can cause the rubber material of intercooler boots to degrade over time, leading to cracks, while excessive pressure can result in the shoes becoming loose or blowing off entirely. For owners of the Dodge Ram 2500/3500, it is crucial to be mindful of Temperature and Pressure factors as they can significantly impact the longevity of the 6.7 Cummins intercooler boots.

Routine maintenance and timely inspection of the intercooler system, including the boots, can ensure they seal properly and function as expected, preventing unplanned downtime and costly repairs. In certain cases, upgrading to a heavy-duty bootkit can further enhance the system’s durability, safeguarding the engine against the detrimental effects of high temperature and pressure.

Key Takeaways

- The condition of intercooler boots is vital for 6.7 Cummins engine integrity.

- Temperature and pressure extremes can compromise boot longevity.

- Regular maintenance and possible upgrades enhance system durability.

Impact of Temperature and Pressure on 6.7 Cummins Intercooler Boots

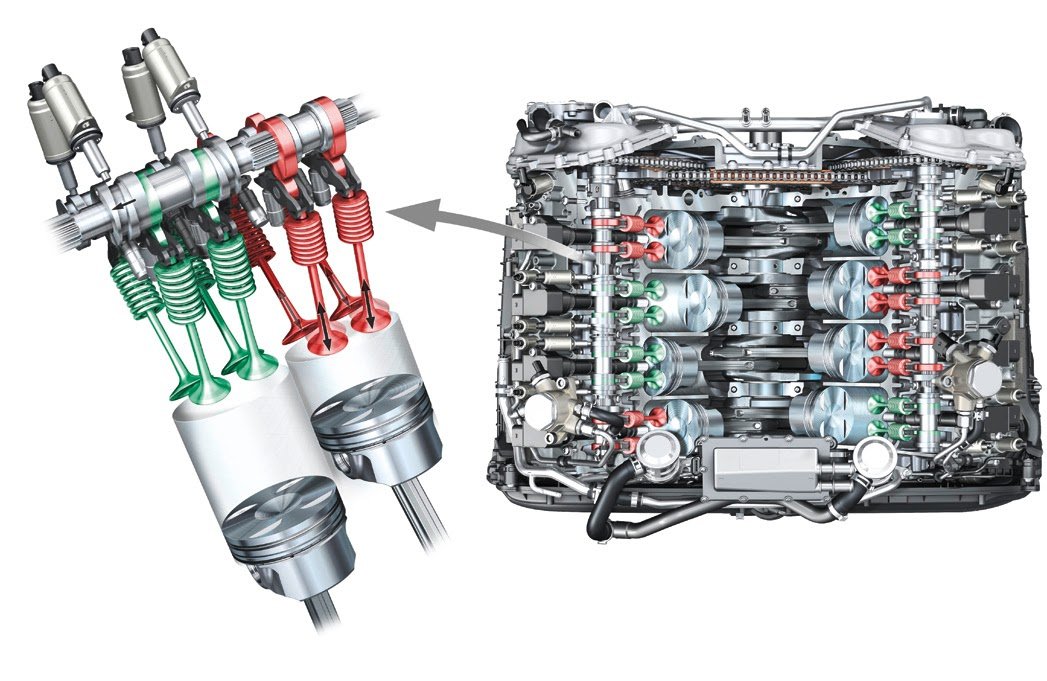

Intercooler boots on the 6.7 Cummins engines play a critical role in managing the balance between temperature control and pressure maintenance, imperative for both the performance and longevity of the engine’s turbocharger system.

Temperature Factors Affecting Boot Longevity

The 6.7 Cummins engine, renowned for its reliability, is not immune to the effects of heat on its components, especially the intercooler boots. Extreme temperatures can lead to material degradation, compromising the integrity of these boots. A notable increase in under-hood temperatures, often seen in demanding environments or with aggressive tuning, can accelerate the wear and tear on these parts. The cooling system needs to perform optimally to regulate the temperature and protect the boots from becoming brittle and failing.

Pressure Variables and Intercooler Boots

In addition to heat, pressure exerts a significant force on the 6.7 Cummins intercooler boots. These boots must withstand continuous pressure fluctuations with the turbocharger imposing high boost levels. Consistent over-pressurization or pressure spikes can strain the boots beyond their intended limits, leading to cracks or blowouts. These defects could potentially reduce overall performance and compromise the longevity of the engine’s turbo system. Thus, maintaining correct compression and ensuring the integrity of the pressure conduits is key for extending the life expectancy of these crucial components within diesel engines.

Maintenance and Enhancement for Durability

Proper maintenance and timely enhancements are critical for the durability and reliability of the 6.7 Cummins intercooler boots. These components are essential for maintaining performance and efficiency in Cummins engines.

Routine Check-Ups and Replacements

Regular maintenance of the intercooler boots is key to prolonging the life expectancy of Cummins engines. Routine check-ups should involve inspecting the boots for any signs of wear, such as cracks or degradation. Replacing these components before they fail can prevent more significant issues and maintain the engine’s efficiency. Keeping track of maintenance schedules ensures the reliability of the system.

- Inspection: Check intercooler boots for damage or wear during regular maintenance intervals.

- Replacement: Substitute worn boots with durable options, considering kits with a lifetime warranty.

Upgrades and Aftermarket Solutions

For those who seek enhanced performance and durability, upgrading to aftermarket solutions can be beneficial. Quality aftermarket intercooler boots are often constructed with superior materials that can withstand higher temperatures and pressures, thus boosting power and reliability.

- Materials: Opt for boots made from high-grade materials that offer better resistance to extreme conditions.

- Upgrades: Consider an upgrade to ensure longevity and improve the performance of your Cummins engine with kits that fit precisely and function efficiently.

Conclusion

Temperature and pressure have an impact on the longevity of intercooler boots in 6.7 Cummins engines. High temperatures can cause the material to degrade, while excessive pressure may lead to cracks and leaks. Proper maintenance and regular checks can extend the life of these components. Owners should pay attention to these variables to ensure optimal performance and durability