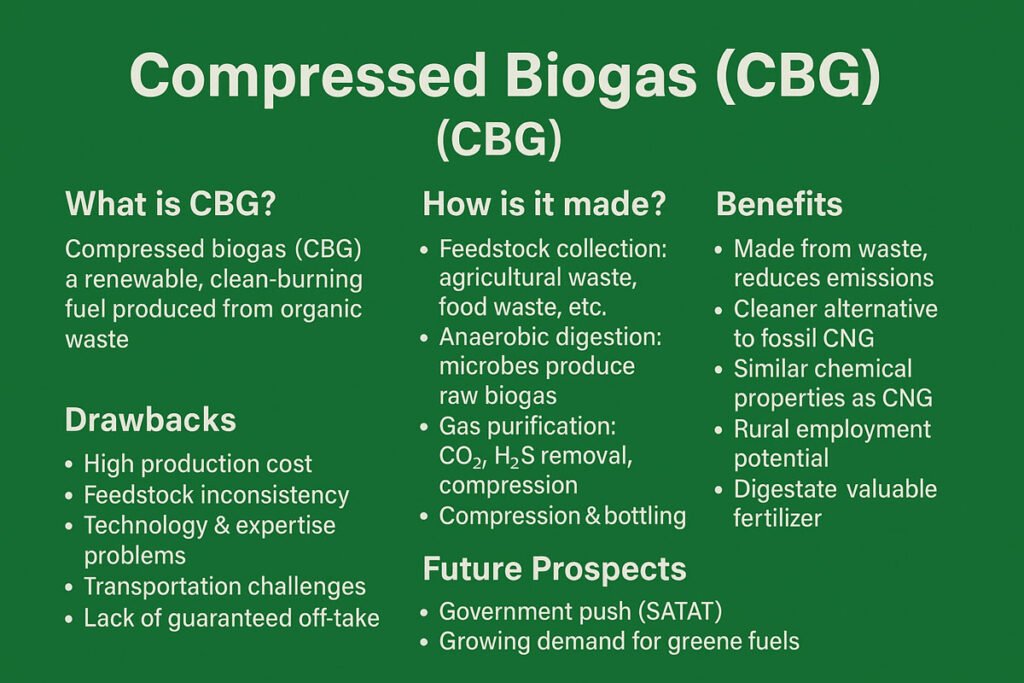

CBG (Compressed BioGas) is a renewable, clean-burning fuel produced from organic waste. Chemically, it is almost identical to CNG (Compressed Natural Gas), primarily methane (CH₄), but unlike CNG, it doesn’t come from fossil sources.

In simple words:

CBG = Purified methane made from waste → compressed → used as fuel

CNG = Methane drilled from underground → compressed → used as fuel

CBG is also marketed under the name “GOBAR-Dhan Gas” in India because cattle dung is a major raw material in rural plants.

How is Compressed BioGas Made? (Step-by-Step Process)

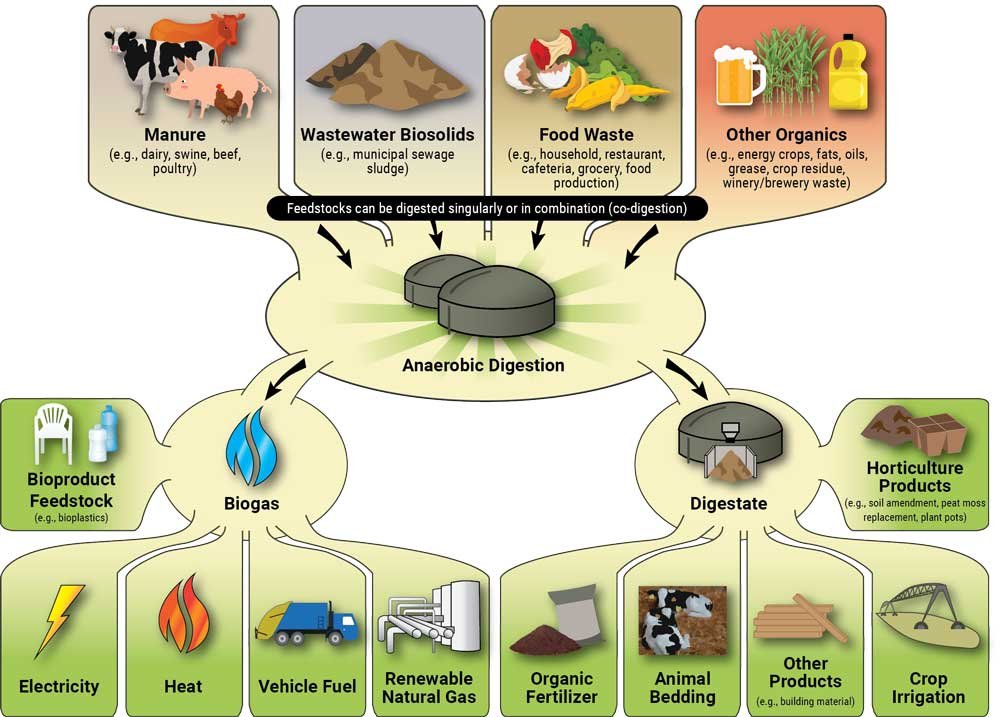

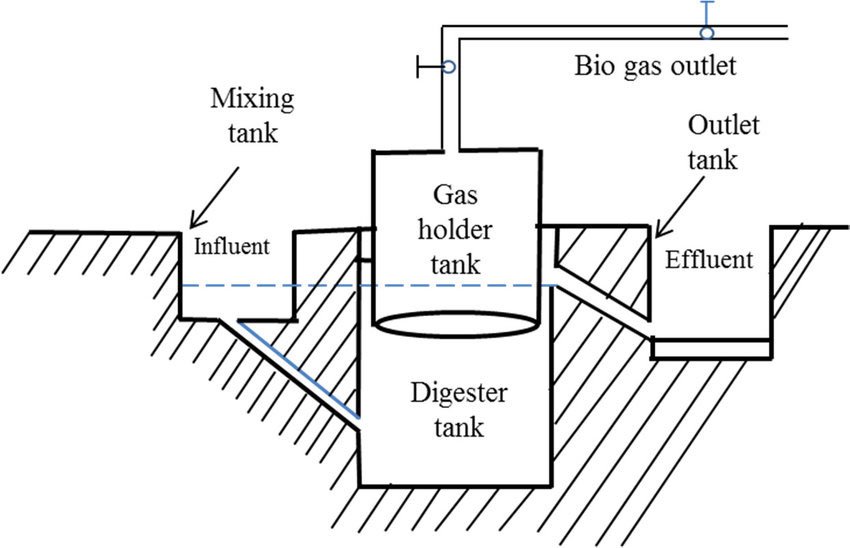

CBG is produced through a biochemical process called anaerobic digestion.

1. Feedstock Collection

Organic waste such as:

- Agricultural residue

- Cattle dung

- Food waste

- Municipal solid waste (wet waste)

- Sewage & industrial organic sludge

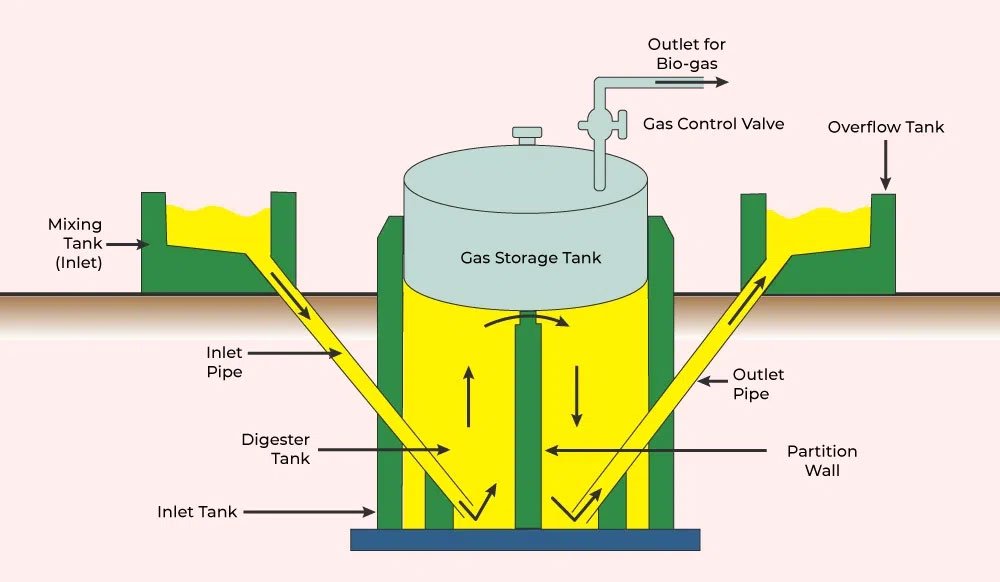

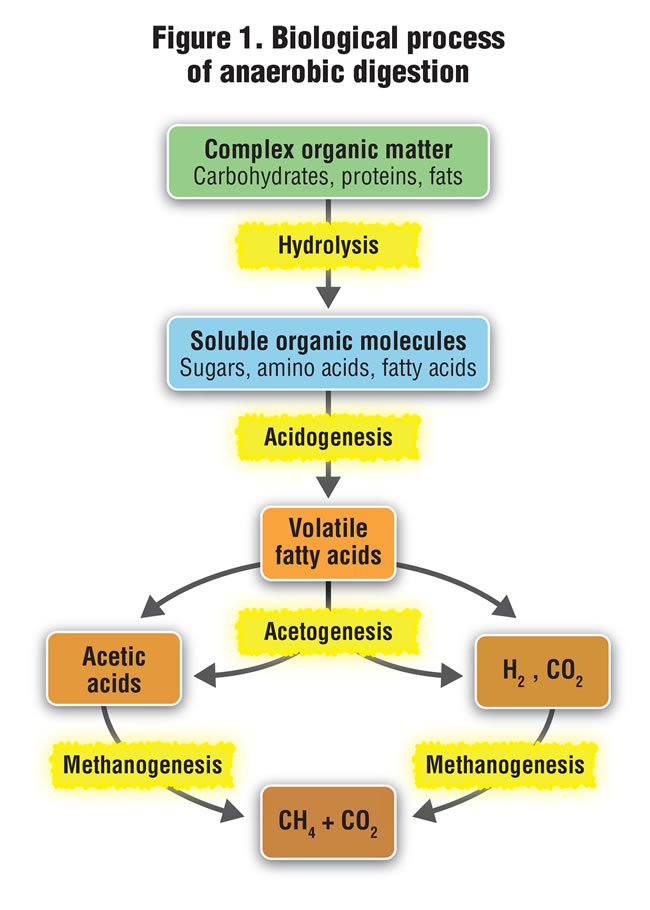

2. Anaerobic Digestion

The waste is put into an oxygen-free digester. Natural microbes break it down and produce raw biogas containing:

- 50–60% methane

- 40–50% CO₂ + H₂S + water vapor

3. Gas Purification & Upgrading

Raw biogas isn’t suitable as a vehicle fuel. It undergoes:

- CO₂ removal

- H₂S removal

- Moisture removal

- Compression

After purification, methane content rises to 92–98%, which matches CNG quality.

4. Compression & Bottling

Purified methane is compressed to 200–250 bar, converted into CBG cylinders, or directly injected into city gas pipelines.

Benefits of Compressed BioGas

1. Made from Waste – Solves a Huge Disposal Problem

Agricultural waste, food waste, and cow dung become raw materials.

This reduces:

- Open burning

- Landfill waste

- Methane emissions from decomposing waste

2. Cleaner Alternative to Fossil CNG

CBG has:

- Lower carbon footprint

- Almost zero sulphur

- Lower particulate emissions

Tailpipe emissions are cleaner than petrol/diesel.

3. Chemical Properties Similar to CNG

This means:

- No engine modification required

- The Same vehicles can run on CBG

- Blending with CNG is easy

4. Huge Rural Employment Potential

Every CBG plant employs:

- Farmers

- Plant operators

- Transporters

- Maintenance teams

Plus, farmers earn by selling cow dung/agri waste.

5. Digestate = Valuable Organic Fertilizer

The by-product is bio-slurry, which becomes nutrient-rich fertilizer.

This reduces dependency on chemical fertilizers.

6. Supports India’s Energy Security

India imports ~85% of its crude oil.

CBG reduces this dependency.

Drawbacks and Challenges of Compressed BioGas

1. High Production Cost

CBG currently costs ₹55–65 per kg to produce but sells at ₹70–75/kg (similar to CNG).

Profit margins are low, which discourages investors.

2. Feedstock Inconsistency

Seasonal agricultural waste

- variable cattle dung supply

= unpredictable gas production

3. Technology and Expertise Issues

Plant failures are common due to:

- Low-quality digesters

- Improper microbial control

- Leakage

- Poor maintenance

4. Transportation Challenges

CBG has to be transported carefully in high-pressure cylinders.

Unlike LPG, the supply network is still weak.

5. Lack of Guaranteed Off-Take

Many plants struggle because:

- Local gas distributors don’t purchase regularly

- Payments get delayed

- Pipeline availability is limited

6. Financial Risk

CBG plants need high upfront costs:

- ₹10 crore to ₹50 crore, depending on size

Banks hesitate due to slow returns.

Future Prospects of Compressed BioGas

1. Government Push (SATAT Initiative)

Under SATAT (Sustainable Alternative Towards Affordable Transportation), India aims to set up:

- 5,000+ CBG plants

- 15 million tonnes of CBG production annually

This is a massive push and improves prospects.

2. Growing Demand for Green Fuels

With rising pollution and climate commitments, industries and transport fleets are shifting to:

- Biofuels

- CBG buses/trucks

- Blended CNG (CNG + CBG)

3. Integration into City Gas Networks

City gas distributors (like IGL, MGL, MNGL) are increasingly open to:

- Purchasing CBG

- Mixing it with CNG

- Supplying through pipelines

Once this becomes mainstream, demand will skyrocket.

4. Strong Fit for Rural Circular Economy

CBG connects:

- Waste → Fuel → Fertilizer → Farming → Waste

This circular chain is ideal for Indian rural ecosystems.

5. Potential Export Market

Countries like:

- Sweden

- Germany

- Denmark

Already use upgraded biogas (biomethane) extensively.

India could become a major exporter if production scales.

Should India Bet Big on Compressed BioGas?

Yes, but cautiously.

India’s waste generation is massive, and CBG is one of the most realistic ways to turn waste into wealth.

But success depends on:

- Better technology

- Consistent feedstock sourcing

- Strong purchase guarantees

- Clear profitability for plant owners

If these challenges are solved, CBG can become:

- A mainstream vehicle fuel

- A replacement for LPG in some sectors

- A huge booster for the rural economy

- A major contributor to India’s clean energy future