What is Air suspension? How does it work?

I shared about suspension a little while back you can check that post here. Today I will discuss Air suspension and its types. So let us see what is Air suspension and how it works.

What is Air Suspension?

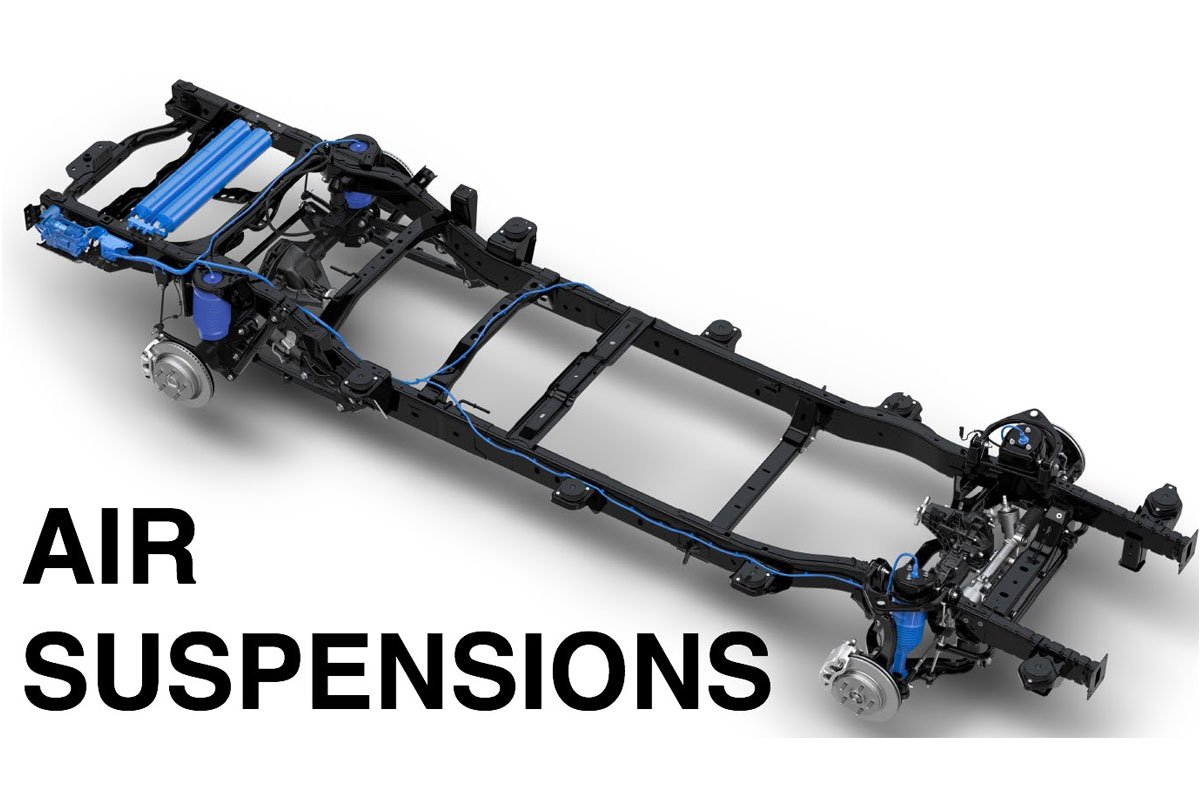

It is a type of vehicle suspension powered by an electric or engine-driven air pump or compressor. This compressor pumps the air into flexible bellows, usually made from textile-reinforced rubber. The air pressure inflates the bellows and raises the chassis from the axle.

So what is the difference between a traditional suspension and an air suspension? The basic difference is we are replacing steel springs and leaf springs with airbags/springs these are rubber membrane which holds pressurized air on which your vehicle is riding on. The traditional suspension has a damper mechanism set to a certain ride control, while the air suspension system uses an air compressor with shock absorbers to maintain the ride control.

How does air suspension works?

There is a frame through which the airline runs and it connects all the airbags. An air pump supplies air to the airbags and maintains the air pressure according to the need. The control unit is the brain of this system which senses everything and manages the air supply and also the ride height using height sensors. The drier is used to remove any moisture in the air which is sucked from the atmosphere. The height sensor maintains the ride height to the level which you have adjusted using the controls.

Consider a situation where you have a truck (Dodge RAM) it has air suspension. There are mostly three levels in which we can adjust the ride height. High for off-road where you get maximum ground clearance. Medium for daily driving where you’re driving on normal roads. Low for high-speed driving which will have minimum air resistance. It also adjusts the ride height even if you add more weight, for example, if you increase the load in the rear normal vehicle will lean back, but the air suspension will sense it and level the ride height.

Types of Air Suspension

Convoluted Air Spring

Rolling Lobe Air Spring

These two systems in air suspension are used to pull air from the environment

Open System

In this system, the air is sucked via the air supply unit and sent to the reservoir and then to the air springs. Here reservoir is used to have control over the air supply to the air springs. When an air spring wants to release pressure, it just releases the air into the atmosphere. That’s the hissing sound you hear in vehicles having air suspension. They release air when coming to a stop to lower the ride height.

Closed System

This system also works the same way, but it does not release air to the atmosphere instead sends it back to the reservoir which can be sent again back to the air springs. This is a better system because it has a quick response time, is more efficient and does make a hissing sound every time the air is released.

Advantages and Disadvantages

- You adjust the ride height of your vehicles

- Getting in and out of the tall vehicles is easy, as you can adjust the height

- Customizable according to the condition of the driving

- Adjust the ride height automatically for lower air resistance while driving on a highway for better fuel economy

- Load levelling which is discussed above

- It also increases the ride quality and hence it is used in high-end cars.

- There is only one disadvantage which is the cost, this system gets expensive with all the options.

Courtesy: Engineering Explained

So Air suspension is good but you need to consider the high cost. If you don’t want a versatile vehicle, which means don’t you use one vehicle for all the purposes then spending extra for this suspension is not worth it. If you add on from aftermarket it is expensive and also repairing this system can be complex and expensive